A better future starts with measurement and science, which is the basis of our sustainable manufacturing practices and targets for reducing emissions, water usage, and achieving zero waste. We also engage with local NGOs and an employee volunteer program to improve the quality of life in our communities.

It’s our people who create the extraordinary, every day. We strive to ensure team members are empowered to reach their full potential by promoting a culture of safety and continuous development. We also invest in mental health resources and hold our facilities to the highest global standards for labor practices.

What defines our approach? We do the right thing, always. Whether we’re helping customers deliver great products, addressing sustainability requirements with suppliers, or collaborating with customers and suppliers to further a more sustainable value chain, responsibility and transparency inform our every action.

Our advancement of sustainability includes clear, consistent communications about our goals, activities, performance, and results.

Environment

43% reduction in absolute scope 1 and 2 greenhouse gas emissions in 2024 from 2019 baseline year1

Health and Safety

10% reduction year-over-year in total case incident rate (TCIR) in 2024

Suppliers

58% of preferred suppliers2 commit to greenhouse gas emissions reduction targets in 2024, progressing us toward our 2025 goal

1 The target boundary includes biogenic emissions and removals from bioenergy feedstocks. Absolute Scope 1 and 2 market-based emissions.

2 Flex commits that 50% of our ‘Preferred Suppliers’ will set their own GHG emissions reduction targets by 2025 and 100% by 2030.

Details our calendar year 2024 sustainability performance

reduction in absolute scope 1 and 2 greenhouse gas emissions in 2024 from 2019 baseline year1

sites within scope2 were validated as zero waste

of our sites with 1,000 employees or more partnered with a local NGO in 2024

1 The target boundary includes biogenic emissions and removals from bioenergy feedstocks. Absolute Scope 1 and 2 market-based emissions.

2 Our 2024 progress puts us 95% towards our 2025 goal of achieving zero waste in 50% of our manufacturing and logistics sites.

Our journey to reduce our environmental footprint and ambition to reach net zero emissions by 2040 focuses on implementing and purchasing renewable energy, optimizing site infrastructure, and partnering with our ecosystem of customers and suppliers on energy and emissions reduction strategies.

Meanwhile, we’re charting a path to zero waste by applying our circular economy practices to reuse, repurpose, and extend the use of materials. In addition to our commitment to decreased water consumption, we participate in the World Business Council for Sustainable Development’s WASH Pledge to increase safe water access at all our workplaces.

3 Per revenue

We don’t just want to just protect the planet — we aspire to uplift and invest in the communities where we operate and empower our employees to do so too. Our community building investment approach is two-fold: strategic initiatives supported by the Flex Foundation and employee involvement globally.

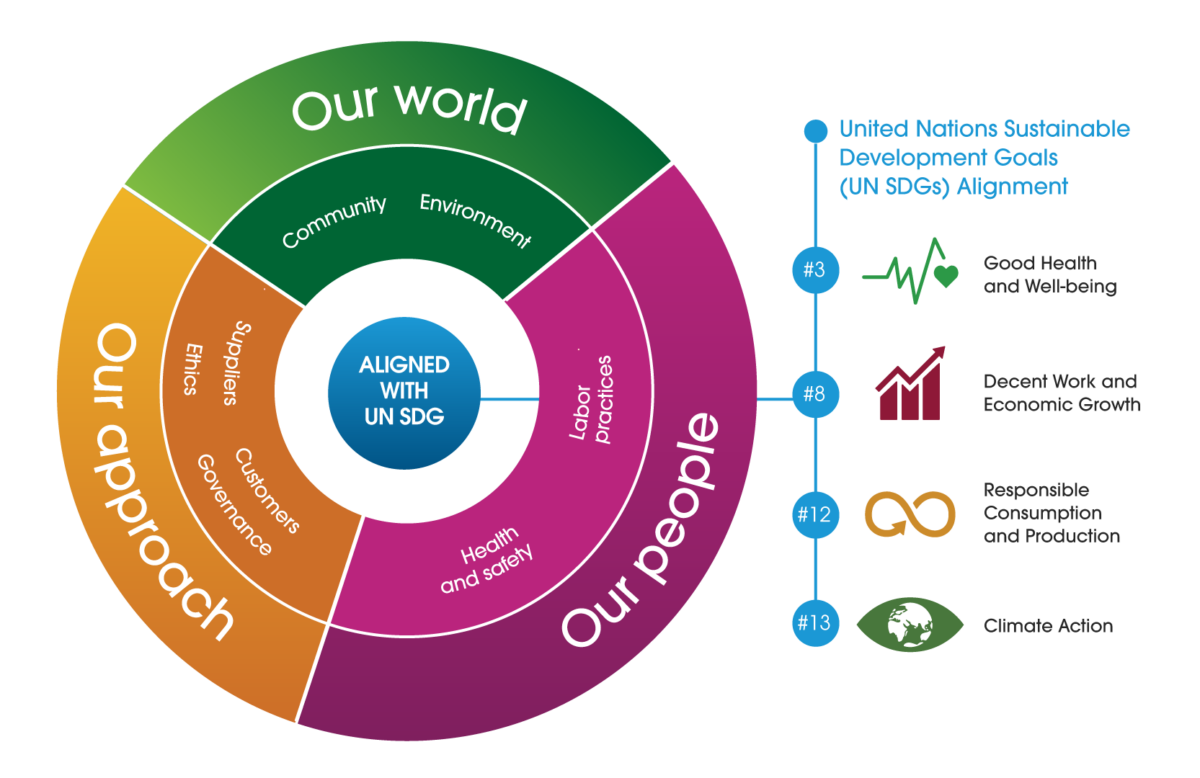

Our community building efforts are aligned with four strategic UN Sustainable Development Goals: #3 good health and wellbeing, #8 decent work economic growth, #12 responsible consumption and production, and #13 climate action.

4 Sites with more than 1,000 employees

Details our calendar year 2024 sustainability performance

decrease in safety incident rate year over year in 2024

of our employees had access to emotional / mental health programs in 2024

average hours of training

per employee achieved in 2024

We promote workforce safety, health, and well-being from all angles. Our strong social management system aligns to the RBA code of conduct as we pursue industry certifications to ensure the respectful treatment of workers and the consistent adherence of responsible business practices.

By investing in advanced manufacturing technologies and staying apprised of equipment safety improvements, we’re continuously designing risk out of manufacturing processes.

We promote and protect human rights to safeguard the fundamental freedoms of our workforce and treat team members with the utmost respect, dignity, and care. This includes providing well-being and development resources.

We recognize the importance of accessible mental health programs to support team members, psychologically and emotionally. We’re continuing to evolve and develop formal and on-the-job learning and upskilling opportunities so that every team member is empowered to prepare for their next role while gaining valuable experience.

Details our calendar year 2024 sustainability performance

of preferred suppliers1 commit to

greenhouse gas emissions

reduction targets in 2024, progressing towards our 2025 goal

of specified customers2 had science-based targets in 2024, progressing us towards our 2025 goal

recognized as a World’s Most Ethical companies® honoree by Ethisphere for leading in ethical business practices for the third consecutive year

1Flex commits that 50% of our ‘Preferred Suppliers’ will set their own GHG emissions reduction targets by 2025 and 100% by 2030.

2 Progress based on our commitment that 70% of our customers by emissions covering purchased goods and services, capital goods, and use of sold products will have science-based targets by 2025, which was baselined in calendar year 2019. Top customer by emissions selection was updated based on the 2023 data. Although 20% of our top customers by emissions do not have an official SBTi target, their strategies and targets are aligned with science-based principles.

We hold our supplier network to the highest ethical standards by requiring strong management systems, transparent reporting, effective social and environmental activities, ethical practices, and comprehensive risk mitigation. We also work to reduce emissions across the value chain by working with suppliers to set reduction targets by sharing lessons learned and scaling best practices.

Commit that 50% of our ‘Preferred Suppliers’ will set their own GHG emissions reduction targets by 2025 and 100% by 2030.

We’re helping leading brands identify the optimal route to reduce emissions, waste, and energy while balancing lead time, cost, and sustainability requirements through our reverse logistics and circular economy services. We also partner with a set of our customers to help them identify science-based emission targets, accelerating a more sustainable value chain.

Commit that 70% of our customers as measured by emissions covering purchased goods and services, capital goods, and use of sold products will have science-based targets by 2025.

Integrity starts at the top and serves as the foundation of trust for our employees, customers, and other stakeholders. In everything we do, we maintain the highest standards of ethical business practices and compliance with integrated scorecards for risk assessment, code of business conduct and ethics training for direct and indirect labor, and more. In addition to local reporting channels, we have a toll-free hotline and online reporting channel available 24 hours, 7 days a week in several languages.

Be independently evaluated as having a world-class ethics and compliance program by 2025.

We never stop evaluating and enhancing our oversight processes and procedures to ensure the highest levels of accountability and transparency, as reflected in our strong ratings in the Dow Jones Sustainability Index (DJSI), Morgan Stanley Capital International (MSCI), and Institutional Shareholder Services (ISS). We also maintain strong oversight through annual review of committee composition.

Continue to maintain high (top quartile) governance standards as measured by investors, proxy advisory firms, and governance best practices.

Details our calendar year 2024 sustainability performance

With these grants, the foundation has aided in climate change mitigation and awareness, disaster relief, community upskilling for people with disabilities and women, technical and vocational training for youth and adults, and more.

The Red Cross is continuously providing support to communities impacted by several disasters across the globe.

Together, the Flex Foundation and Red Cross have positively impacted communities affected by floods, earthquakes, wildfires, and other natural disasters, allowing our employees to contribute as volunteers in the communities where we operate and online through virtual MapSwipe volunteering.

Planet Water addresses global water poverty by providing clean water access and hygiene education programs which have been implemented in Guadalajara, Mexico; Batam, Indonesia; and Cebu, Philippines.

Flex employees continue to donate their time to partner with Planet Water in sites around the world.

Give2Asia aims to strengthen communities in Asia by making cross-border giving easier and more effective.

The Flex Foundation supported several projects that give economic opportunities to young people, accelerate climate change mitigation, progressed COVID-19 relief efforts, provide disaster response and services for migrant children, among others.

The World Wildlife Fund for Nature aim is to empower and amplify environmentally responsible entrepreneurship in Armenis, Romania.

The Flex Foundation supported the launch of several local family farms which brought regenerative farming practices and jobs to the area, benefiting the ecology and community.

As part of their commitment to protect environmental resources, the SOS Mata Atlântica project monitors eight hydrographic regions in the Atlantic Forest in Brazil.

The project also maintains groups of volunteers who participate in the “Observing the Rivers” program which aims to preserve the water quality of rivers, streams, and other bodies of water in the localities where they live. This project will strengthen 20 existing water quality monitoring groups in the Sorocaba, Piracicaba, Capivari, and Jundiaí water basins.

The Flex Foundation is continuously working to support organizations that uplift the communities where we serve, generating positive change and strategically supporting global, sustainable calls to action. The Flex Foundation processes applications and awards grants twice each year. For more information on our community grants program and giving strategy, contact, Sustainability@flex.com.

Details our calendar year 2024 sustainability performance