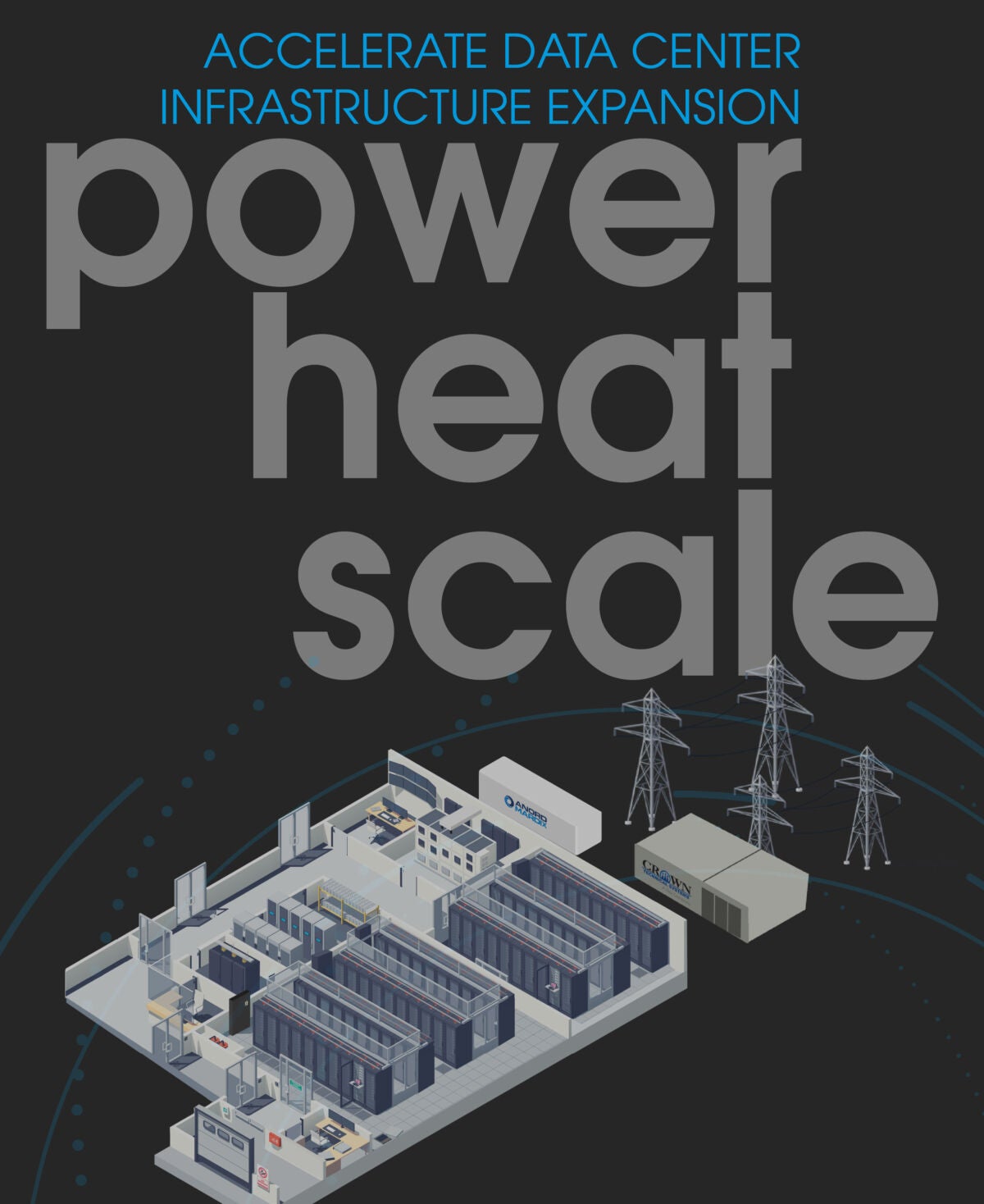

We combine these offerings with our decades of expertise in advanced manufacturing, supply chain, and product lifecycle services to support data center operators speed deployments and address the challenges of power, heat, and scale.

Our AI infrastructure platform for AI and HPC environments integrates power, cooling, and compute into pre-engineered, modular designs to enable operators to speed deployment by up to 30%.

Partner-friendly, the Flex AI infrastructure platform easily adapts to customer-preferred OEMs with a flexible, open architecture that champions innovation, performance, and efficiency.

Today’s manufacturing ecosystems require more agile and reliable deployments to end markets.

Flex supports customers through a combination of:

A global footprint that allows proximity to end markets, enabling companies to better align production with demand signals

Products tailored to business requirements, local needs, and sustainability goals

The outcome? Timely delivery of IT, power, and cooling infrastructure to support data center expansion.

Flex helps extend your product lifecycle and maximize ROI by servicing end-of-life for compute and power infrastructure. Our extensive reverse logistics, repair, refurbishment, asset recovery, and recycling capabilities enable customers to enhance infrastructure value and minimize downtime.

FreeFlow, a Flex marketplace, enables customers to tap into additional revenue streams and accelerate sustainability through an inventory management platform for retail, returned, obsolete, or excess stock.

A trusted, resilient global supply chain is critical to faster, more reliable data center deployments. Our large and diversified supply chain enables customers to overcome logistical and sourcing challenges in any region across the globe.

We bring together a diverse supply chain network, decades of experience, expertise, and technological investments to deliver key advantages to data center customers, including:

Flex Pulse® is our proprietary suite of intelligent supply chain tools, designed to optimize processes, enhance decision-making, and bolster resilience.

Flex offers a portfolio of proprietary products designed to improve efficiency and performance—enabling data center operators to overcome the unprecedented challenges related to power, heat, and scale that they face today.

Grid-to-rack critical power solutions

Revamp power delivery to support AI workloads.

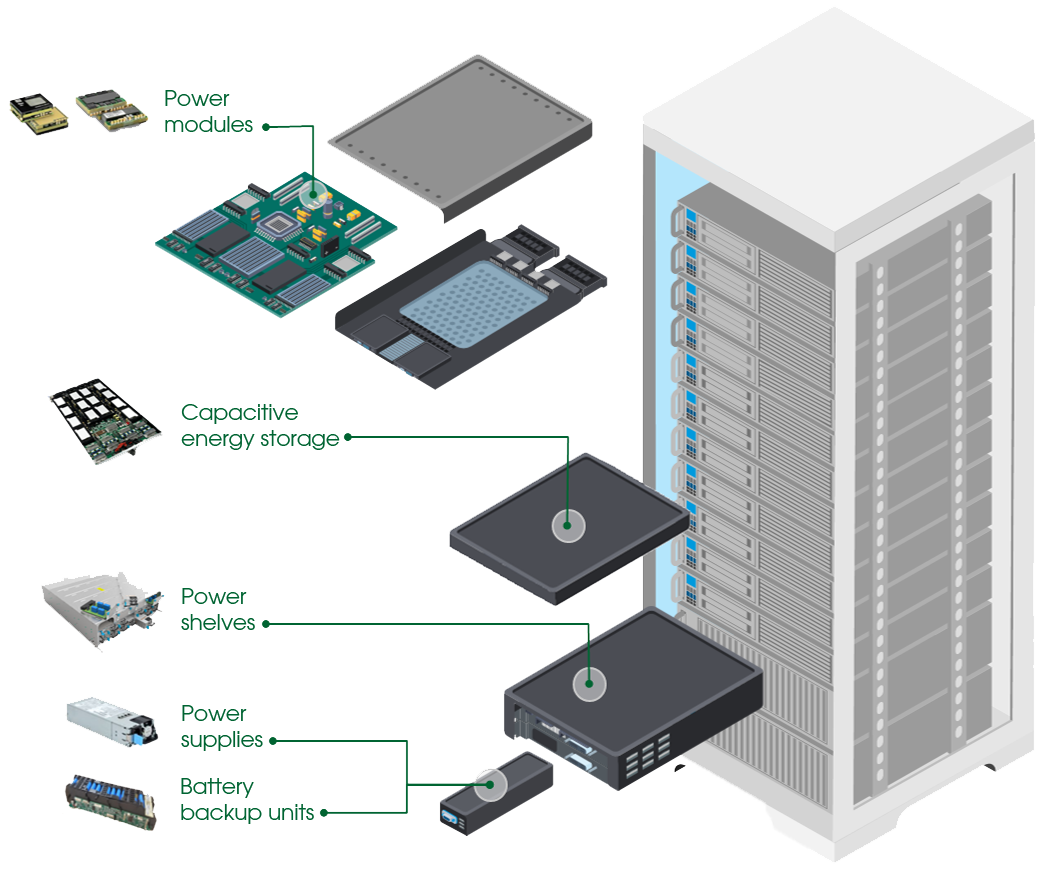

In-rack power solutions

Efficiently manage and distribute power to the IT equipment within a server rack.

Chip-level power management

Design solutions years in advance of new product launches.

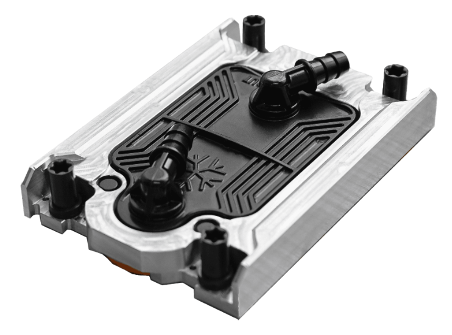

Direct-to-chip liquid cooling

Support AI and high-performance compute environments.

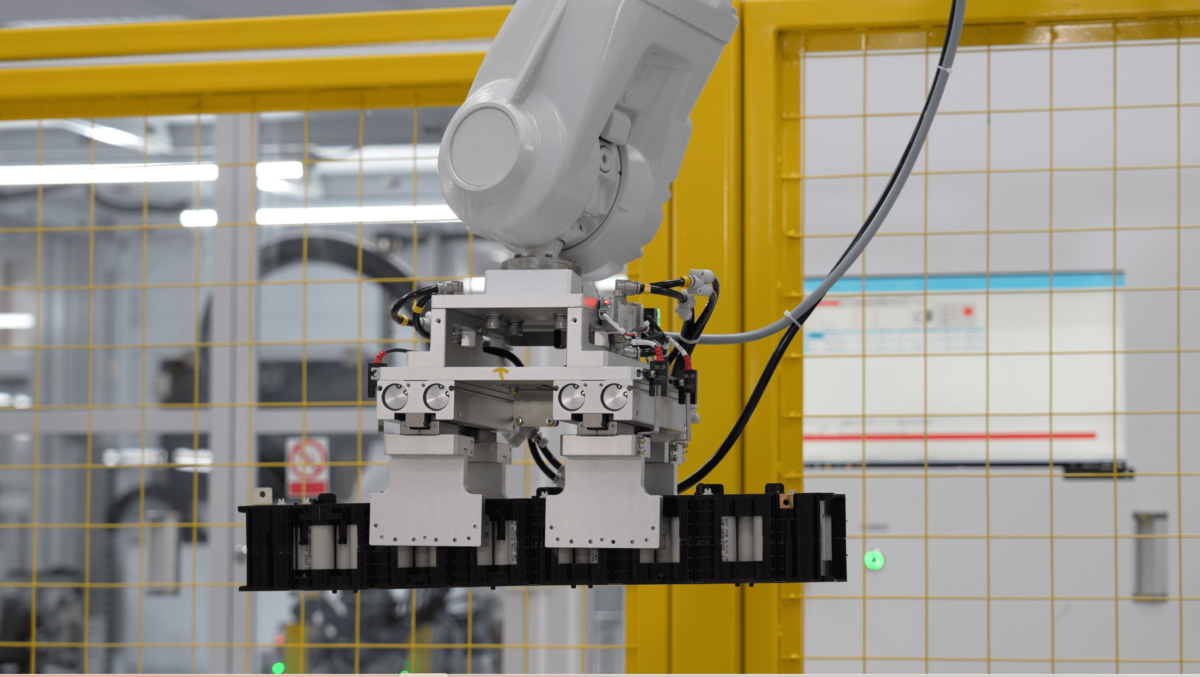

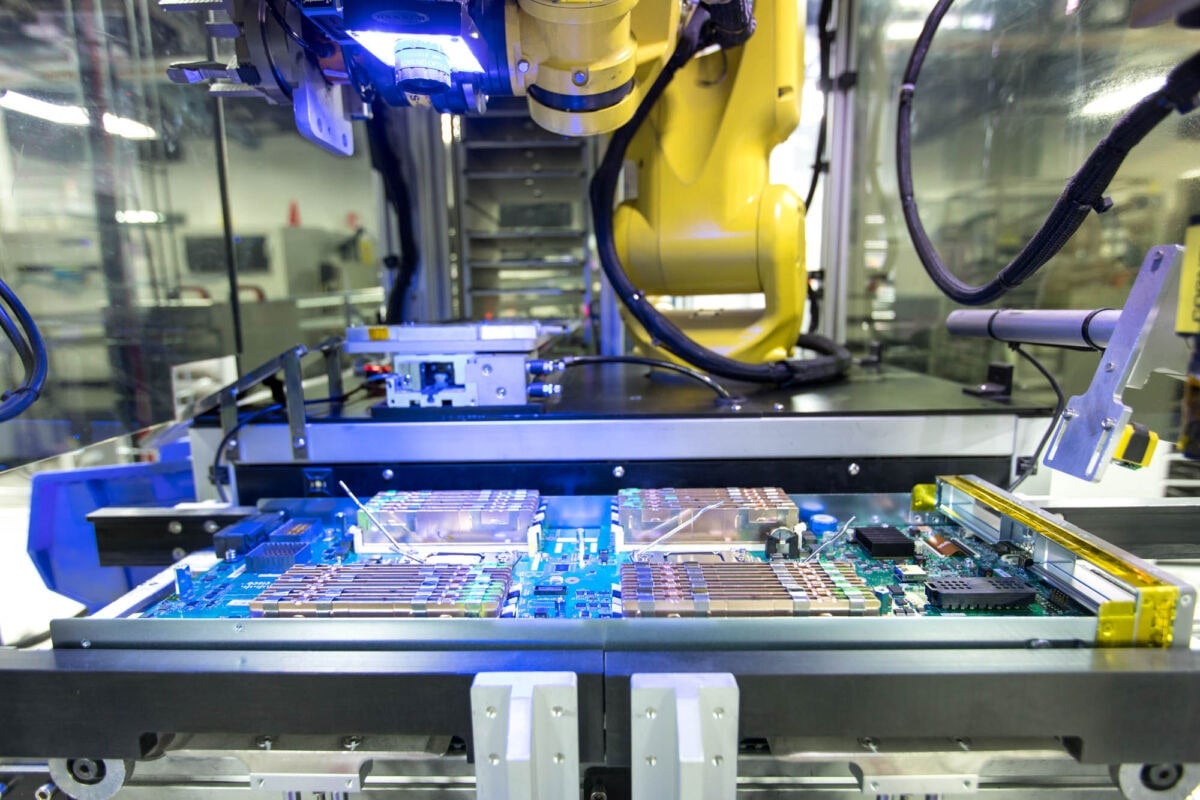

Vertically integrated system rack manufacturing services

Bring together compute, storage, network, power, and cooling technologies.

Data center services

Expand data center capacity faster and more cost-effectively worldwide.

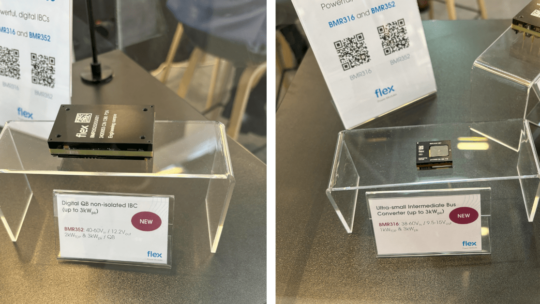

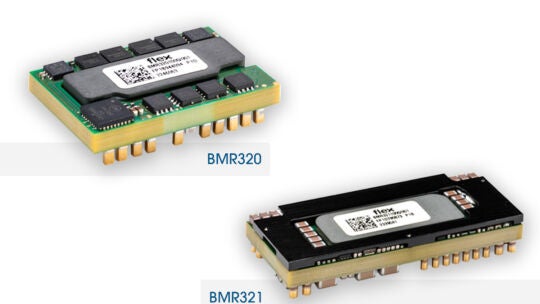

We provide isolated and non-isolated, regulated and unregulated DC/DC solutions with up to 3kW peak power—maximizing system efficiency while minimizing power dissipation.

For customers seeking more tailored solutions, we offer custom products that are adapted to their unique data center needs and requirements. Products available for customization include power shelves, capacitive energy storage systems (CESS), and vertical power delivery (VPD) systems.

Flex has extensive experience designing for the data center and the latest processes and technologies to support your custom needs. Our intellectual property in power supply technology boosts efficiency and gets you to a final design faster and more reliably.

Data center operators require power solutions that enable them to reduce complexity and accelerate deployment. The proprietary products in our portfolio come together to deliver safe, reliable, and high-quality critical power solutions for the data center.

Anord Mardix, a Flex company, specializes in critical power solutions and offers:

Crown Technical Systems, a Flex company, designs and manufactures reliable power distribution products, including:

Coreworks, a Flex company, is a trusted source for standard, semi-custom, and fully custom components for hyperscale data centers. Its broad portfolio includes electrical, mechanical, connectivity, and liquid cooling technologies that support flexible engineering, resilient supply chains, and accelerated deployment.

We offer more than the products to manage your data center power demands. Through Anord Mardix, a Flex company, we provide field services for seamless deployment and efficient management of your supply chain solutions.

Coreworks, a Flex company, provides customized mechanical and interconnected solutions, complemented by an extensive selection of standard electrical components. Sourcing components through Coreworks helps accelerate hyperscale data center builds with precision engineering and seamless integration.

To stay competitive, data center operators need to maximize compute capacity. This requires rapid, reliable delivery of racks and enclosures tailored to meet higher density requirements.

Flex offers both custom and industry-standard enterprise racks and enclosure products ranging from fan trays and chassis to large outdoor and indoor cabinets, integrated racks, and highly cosmetic enclosures. Our standard rack solutions are built on Open Compute Project (OCP) OrV3 standards, providing a proven, industry-standard approach to high-density compute infrastructure.

Racks are designed to 19” and OCP standards for universal data center usage.

We offer our customers tailored node and rack-level integration solutions for their business requirements, technical specifications, and time-to-market advantages. Our global supply chain integration and pretested rack designs reduce deployment complexity and lead times.

Capabilities at the customer campus include the fabrication of racks, nodes, and assemblies.

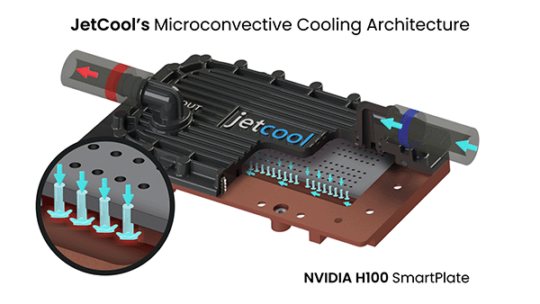

Delivering precise, high-efficiency cooling directly to chip-level hot spots to reduce thermal resistance and improve system performance

Delivering configurable components that ensure compatibility, reliability, and speed

In-rack and in-row CDU products to effectively manage heat in power-intensive environments

Flex offers a range of services to help customers scale liquid cooling solutions faster and more confidently. We combine our expertise in in-rack systems, deployment, and long-term operational management to support SmartSense CDU customers at various stages of the product lifecycle.