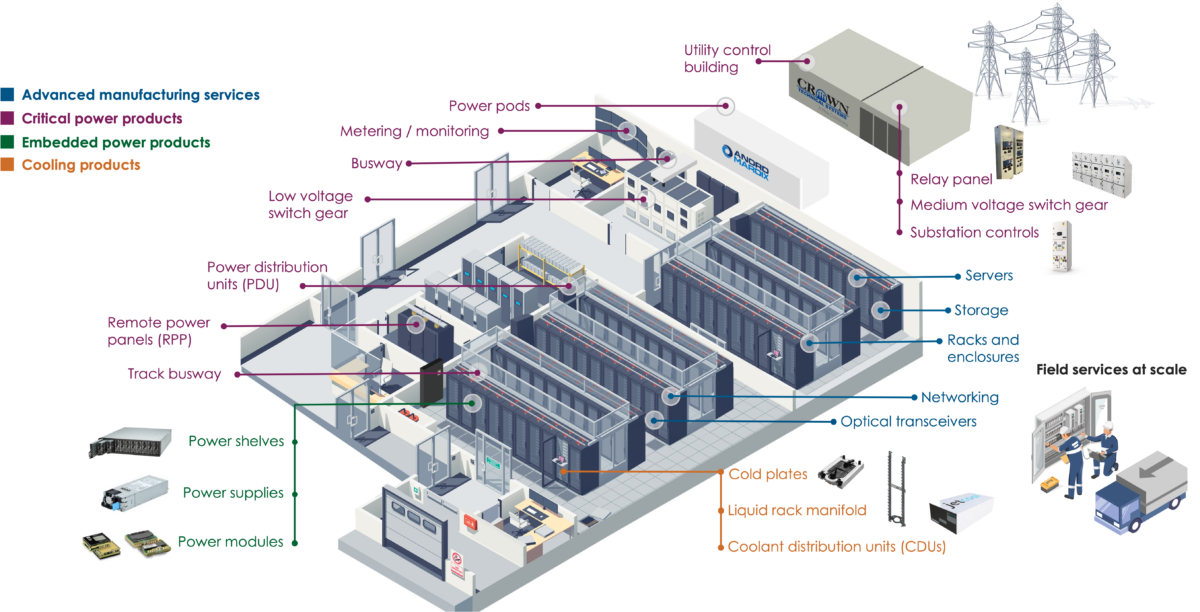

Overcome data center power, heat, and scale challenges

With competitiveness and data center capacity tightly intertwined, choosing the right partner to deliver next-generation power and cooling solutions at scale is central to data center operators’ growth strategies. Flex enables companies to expand data center capacity faster and more cost-effectively with advanced manufacturing, a robust portfolio of critical and embedded power and cooling solutions, vertically integrated system rack manufacturing services, and end-to-end lifecycle services available in every major region of the world. Flex offers:

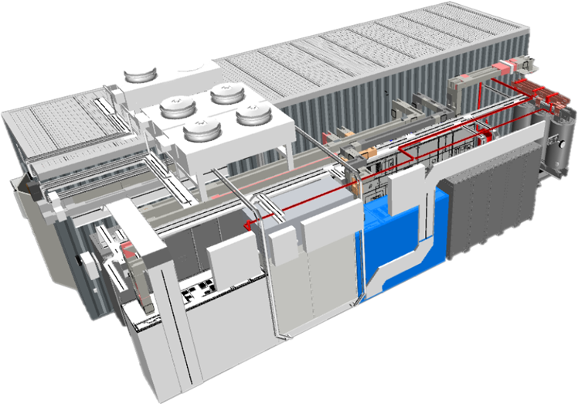

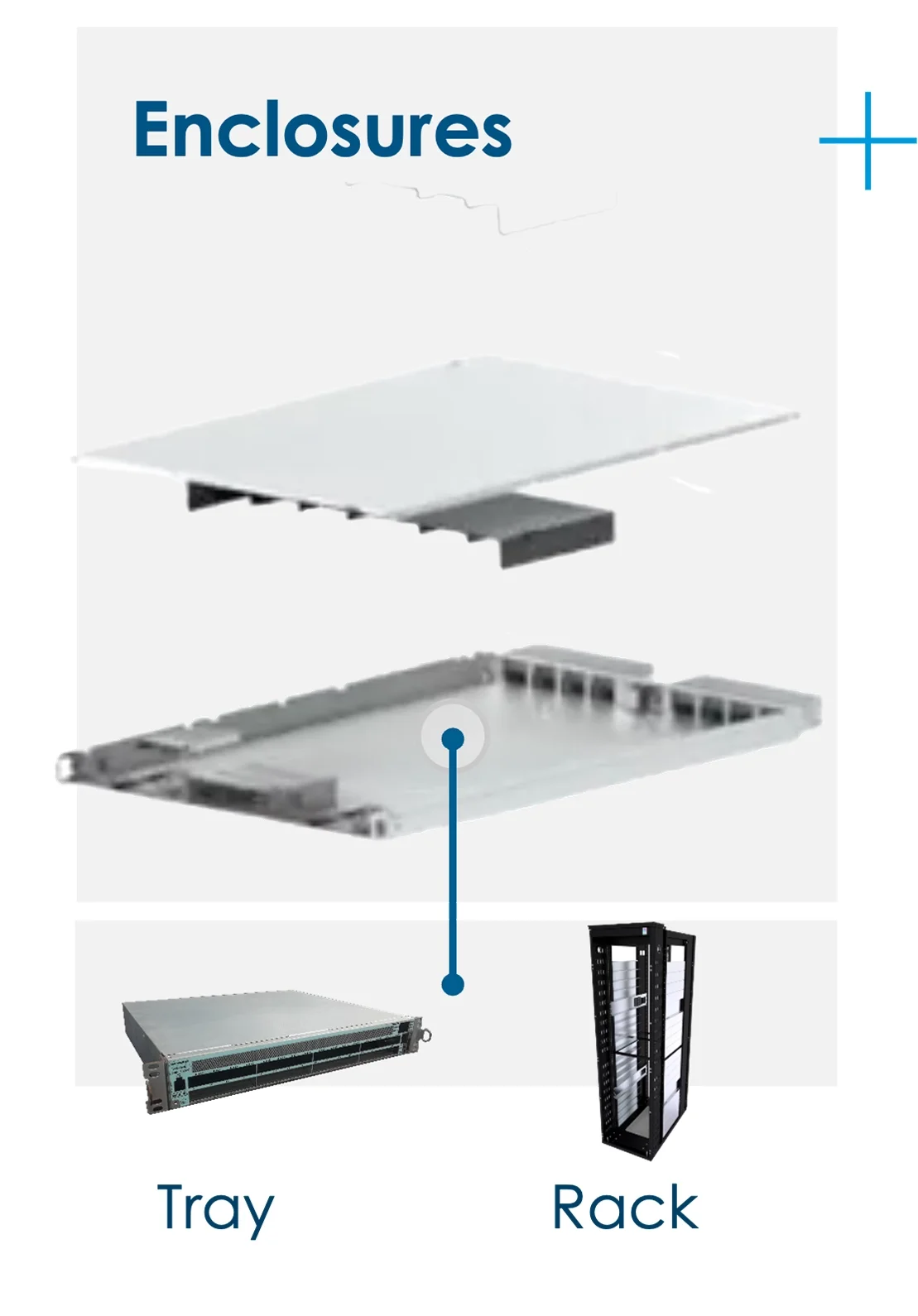

Advanced manufacturing services

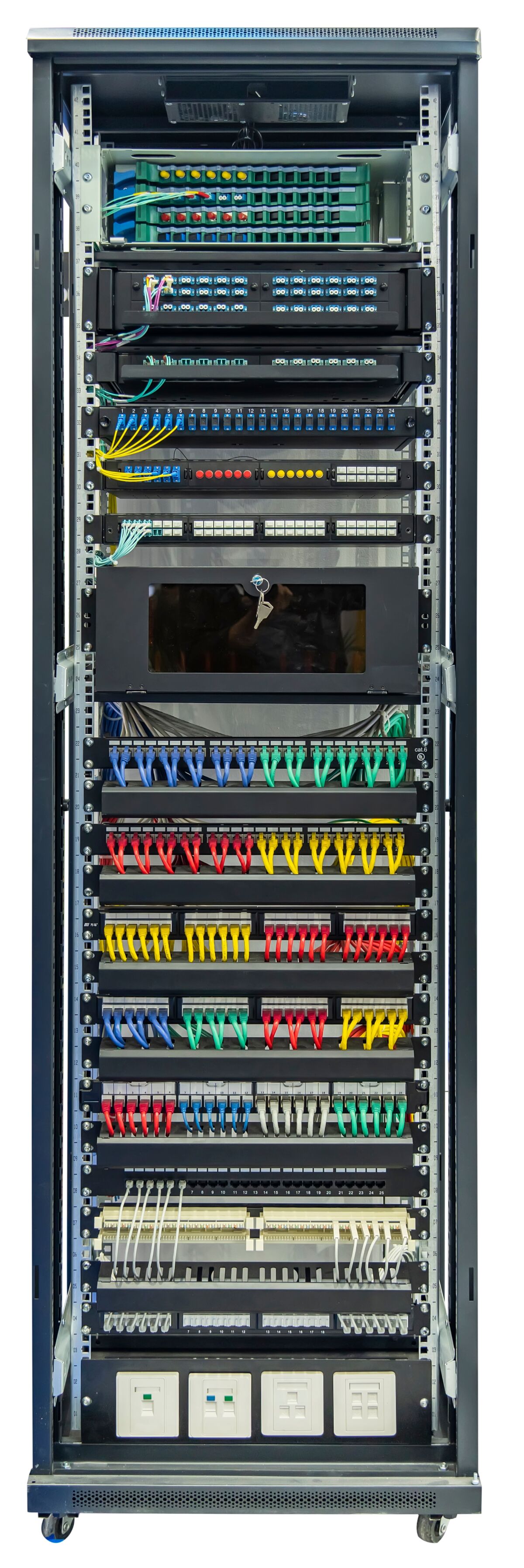

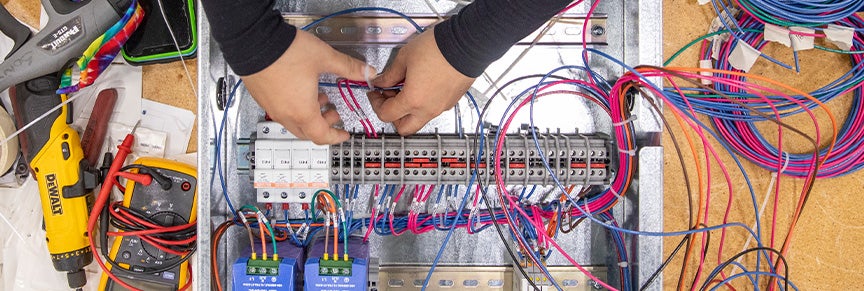

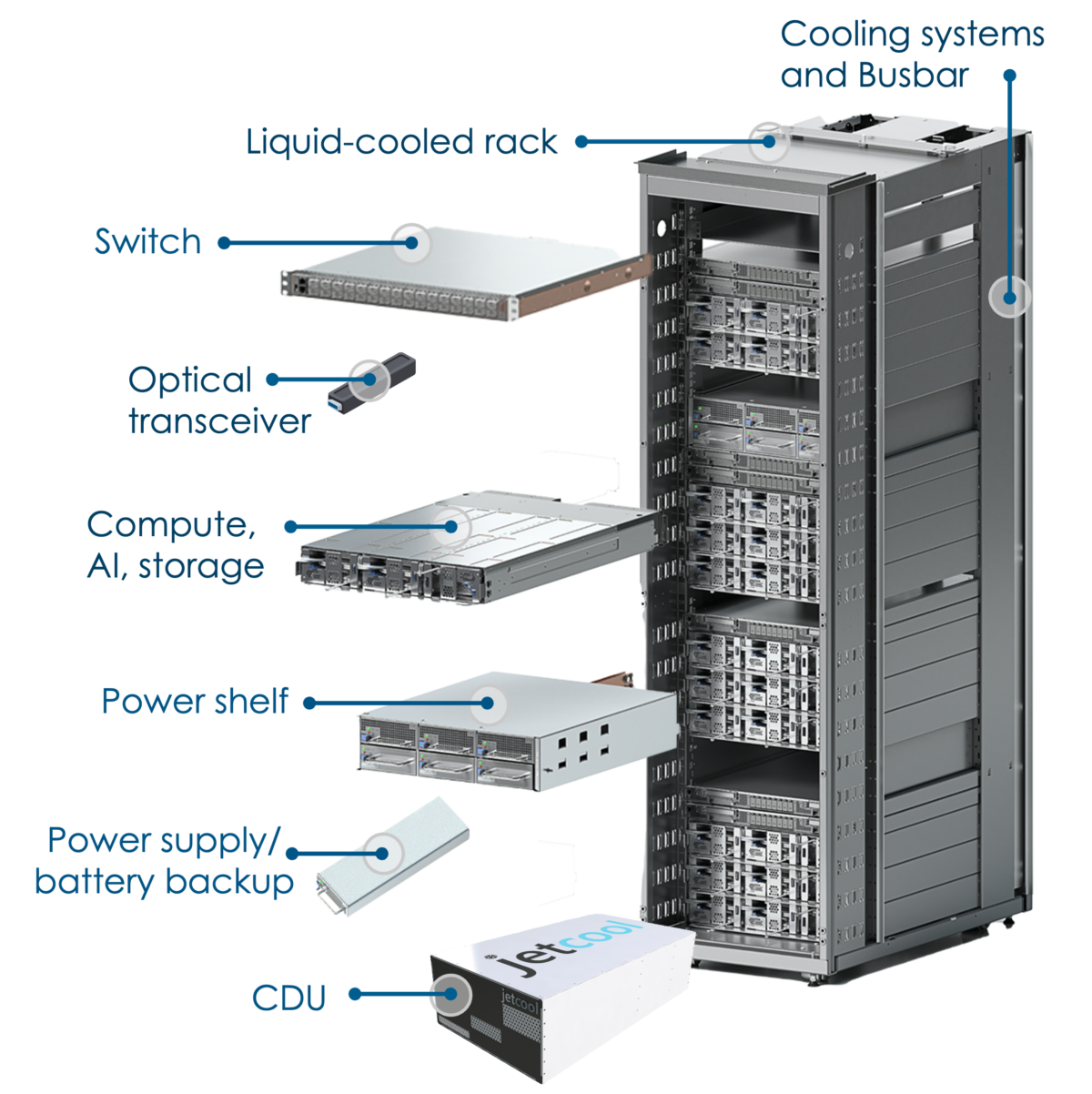

that support the mass deployment of vertically integrated data center racks, from materials sourcing and private-label components to the design, fulfillment, manufacture, and maintenance of servers, storage, racks, cabling, switches, busbars, power shelves, cooling technologies, and battery backup.

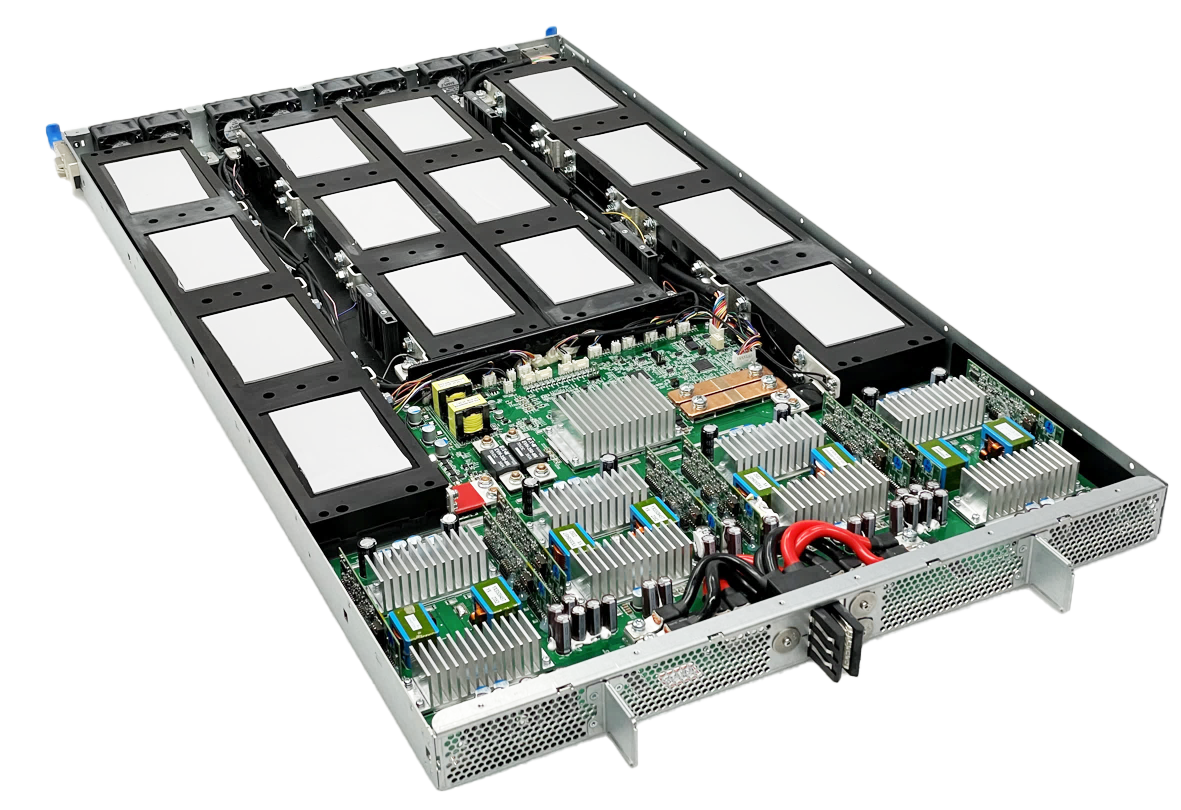

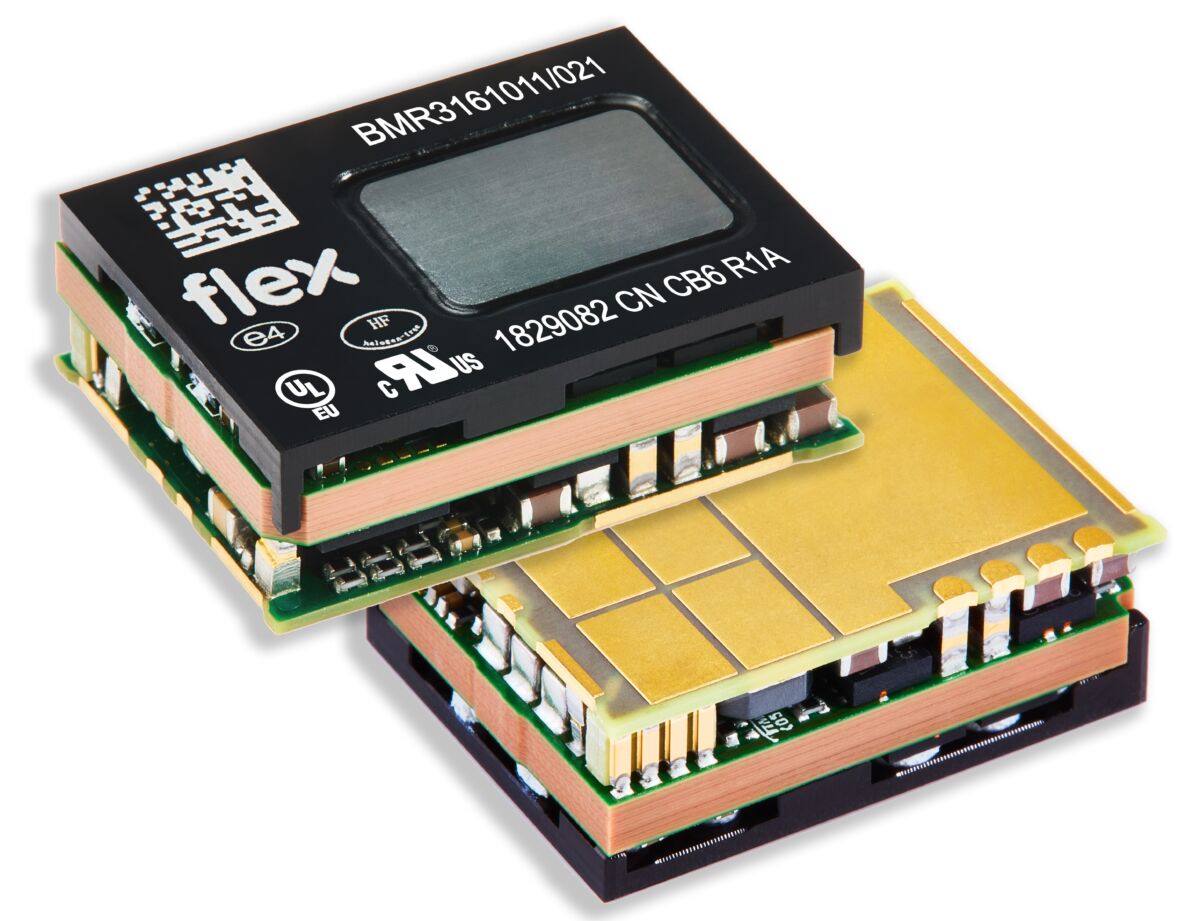

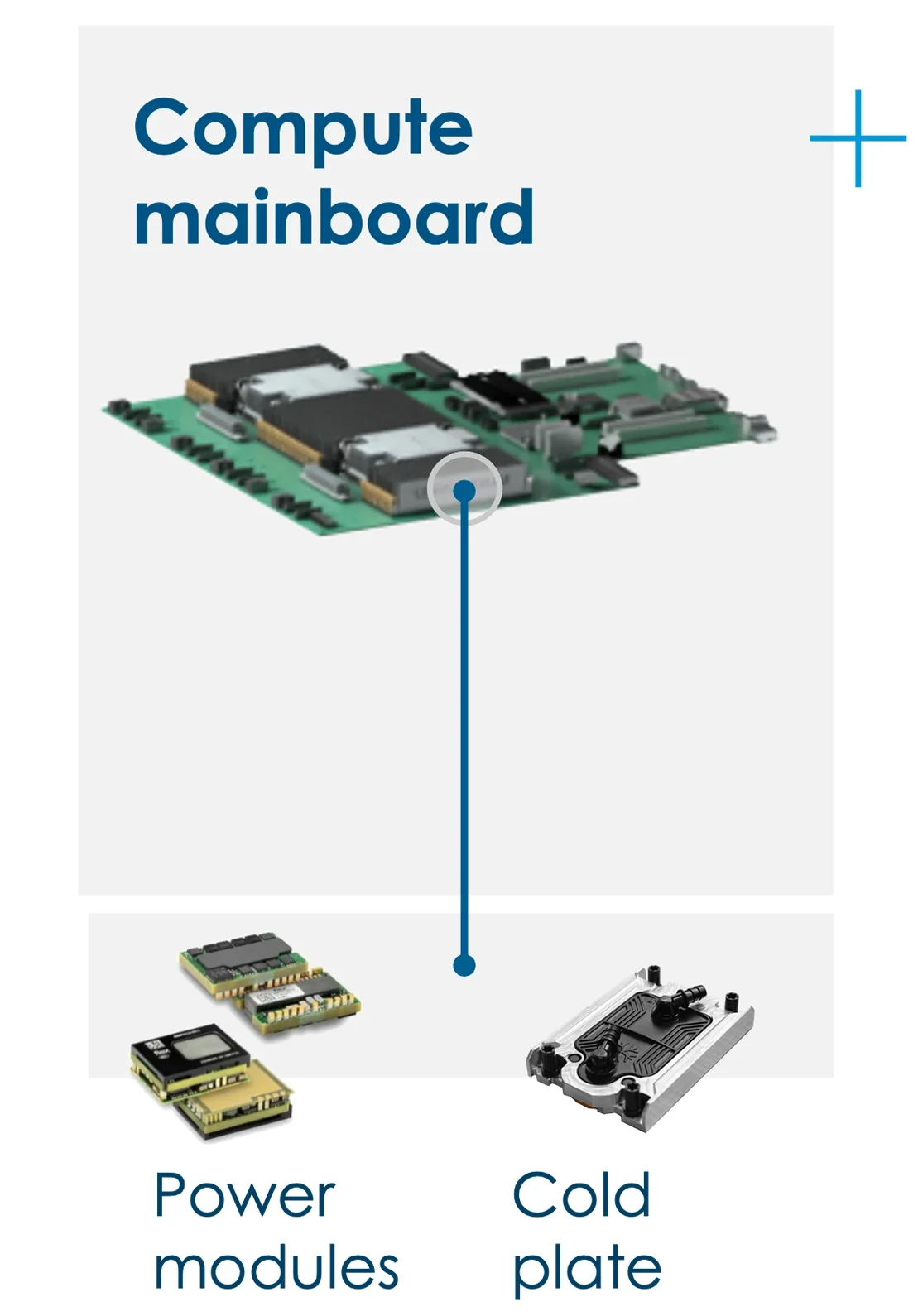

Power products

that enable data center operators to more efficiently manage power through innovative critical power infrastructure—such as switchgear and PDUs—and embedded power at the server and rack levels—such as power modules and power shelves.

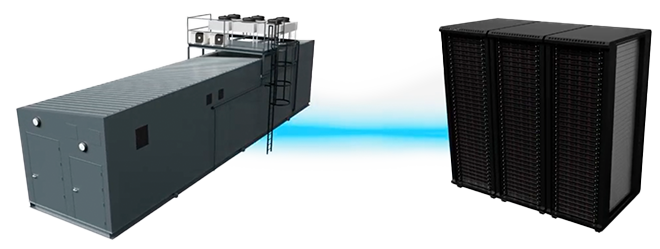

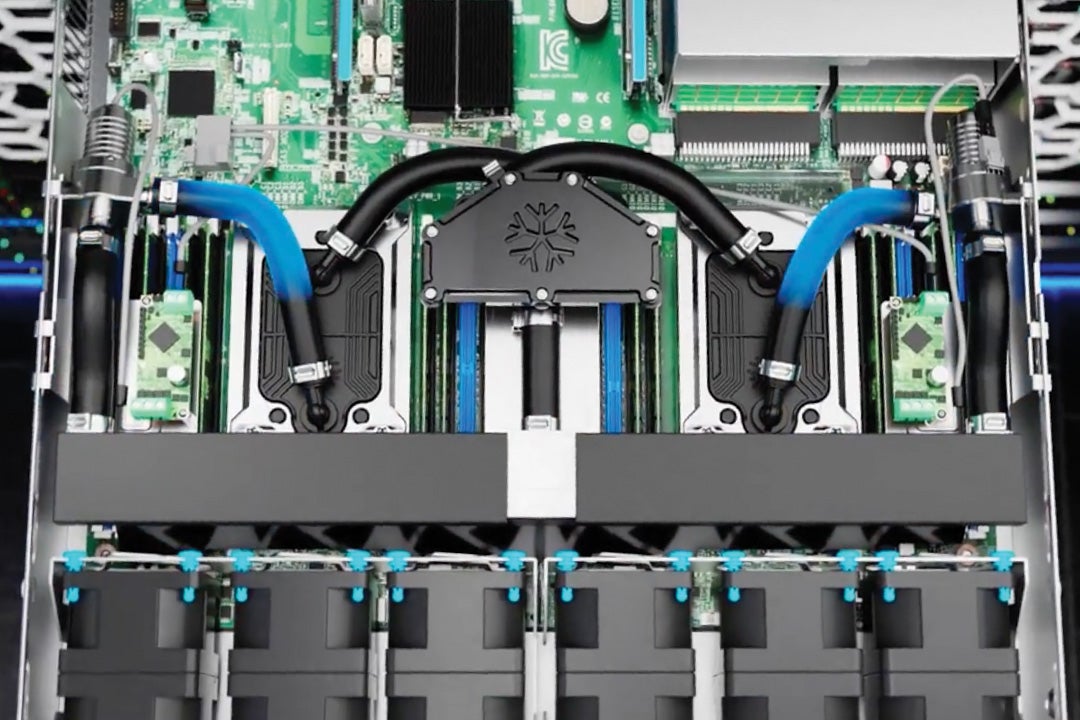

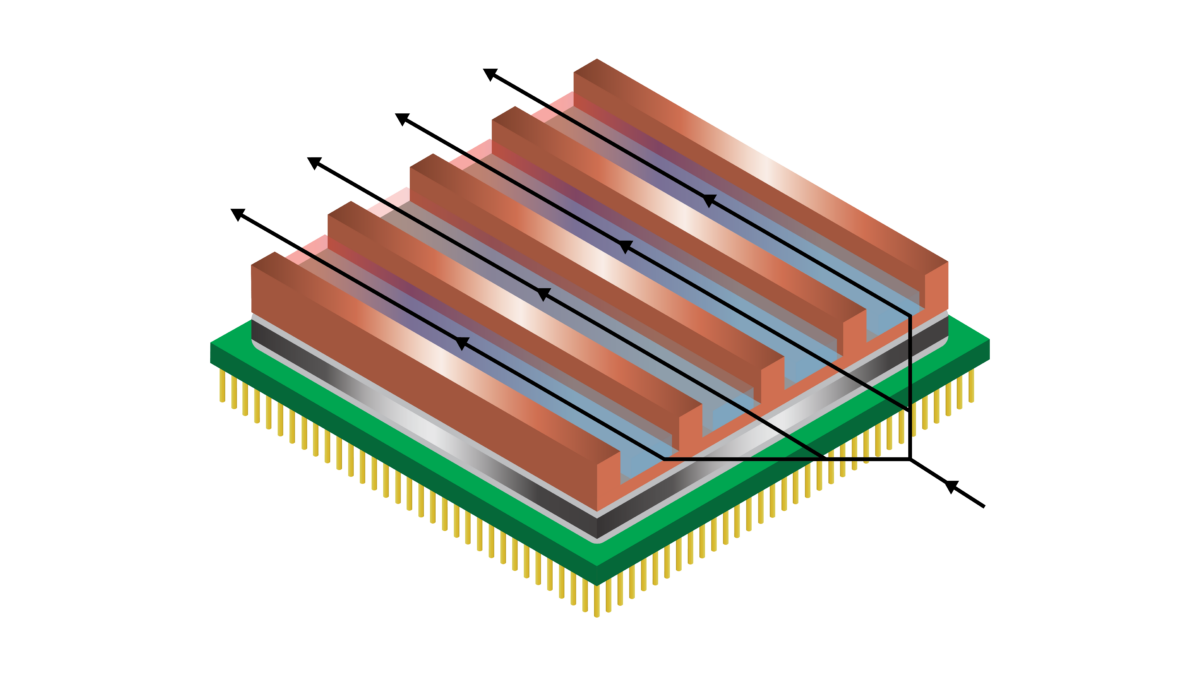

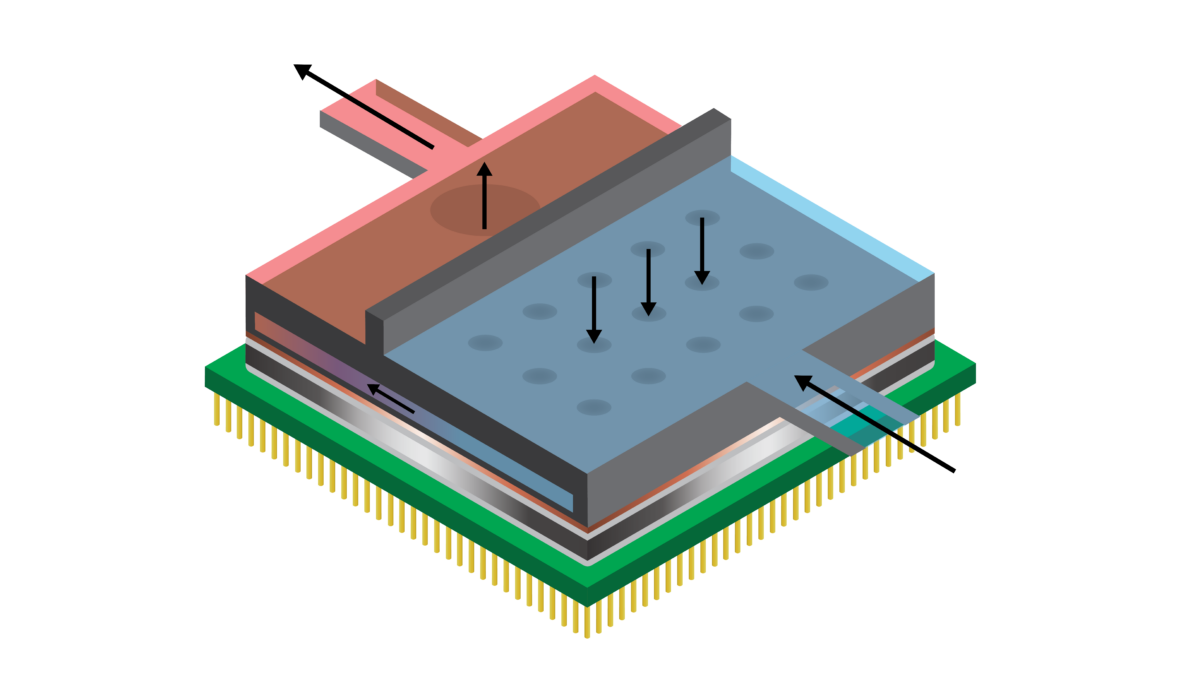

Cooling technologies

including direct-to-chip liquid cooling modules and coolant distribution units that address the challenges of thermal density and increasing rack power.

Specialized end-to-end capabilities

to optimize and streamline the product lifecycle, and to seamlessly and sustainably design, build, deliver, and service products at scale for customers with increased quality, productivity, and speed across a global footprint.

Accelerate data center infrastructure expansion at scale with advanced manufacturing services, innovative power and cooling products, and data center services from Flex.