Leveraging a supply chain and manufacturing partner’s expertise

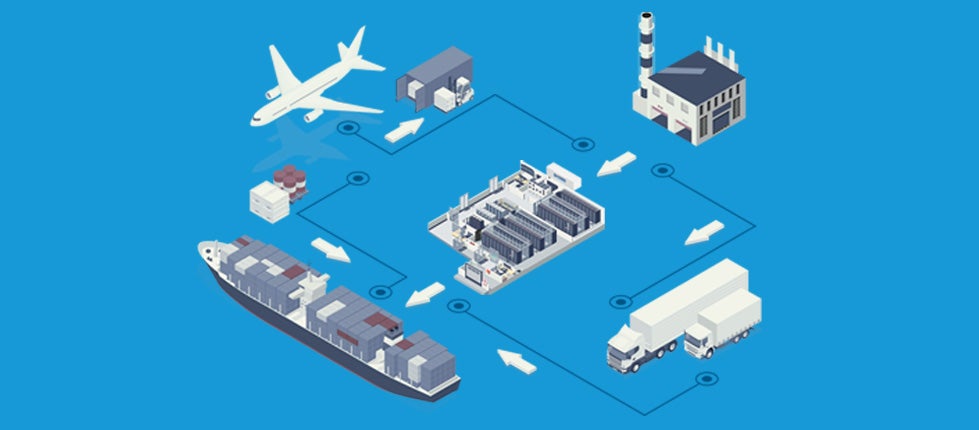

Engaging a supply chain and manufacturing partner with deep data center expertise and global breadth, scale, and capabilities enables companies to transform their inbound, operational, and outbound supply chains for data centers.

At Flex, we work with customers around the world to deliver benefits including:

- Proximity to customers: By localizing their manufacturing and fulfillment sites, data center companies can respond more quickly to market demands and deploy faster.

- Reduction of operational costs: Companies can tap into localized incentives and streamline their supply chains to reduce transportation costs and lead times, resulting in cost savings down the line.

- Streamlined inventory management: We operate through multiple regional centers that enable operations to scale up or down based on demand fluctuations—with no concerns about gaps in supply.

- Sustainability benefits: By guiding our customers through strategic location selection, materials sourcing, fulfillment and circular services, and more, we help them alleviate environmental impacts and meet sustainability goals.

How Flex can optimize your data center supply chain

At Flex, we leverage a diverse supply chain network and decades of experience, expertise, and technological advancements, to help customers across a broad array of industries keep production on track.

For example, a company might wish to reorchestrate its fulfillment to support North American data centers. Flex can work with customers to analyze supply chains and localize them so that they can mitigate risk, optimize inventory carry costs, reduce networking capital, and minimize overall environmental impacts.

In one example, we worked with a customer who required recalibration of its supply chain to capture potential financial and environmental savings. Through strategic supply chain analysis, value chain optimization, financial and environmental impact analysis, and more, Flex simulated a scenario in which the customer would move its data center fulfillment and asset recovery from a U.S. domestic site to their vertically integrated Flex manufacturing site in Guadalajara, Mexico. The simulation found significant opportunities for cost savings, a reduction in carbon footprint, and even shorter delivery times.

Supply chain optimization with Flex Pulse® Network Design

This tool is a value chain analysis and planning application that can help data center customers evaluate current and projected performance, identify critical trade-offs, and solve business challenges using advanced simulation and optimization technologies.

Another strategy is relying on vertically integrated data center rack solutions that are designed, manufactured, delivered, and maintained from our cloud-focused locations around the world. By leveraging our existing capabilities and switching to more readily available materials—which we can help you identify and source—our customers receive immediate cost savings. In the mid- and long-term, we continue to work with customers to deliver strategic supply chain insights that drive data-driven decision making for bigger savings and greater supply chain resiliency.

Work with us to mitigate risk and deploy faster

Flex stands at the forefront of supply chain optimization for data center customers, uniquely positioned to address the pressing challenges of today’s rapidly evolving landscape. With our extensive expertise and global reach, we empower businesses to navigate time-to-market pressures, manage costs effectively, and streamline inventory management while aligning with sustainability goals.

By partnering with Flex, data center operators can leverage our innovative solutions—such as proprietary power products, data center IT infrastructure technology, advanced manufacturing capabilities, and lifecycle services—to enhance operational efficiency and reduce environmental impact.

The extent to which companies and investors in the value chain are able to speed the build-out of those centers could determine their fortunes.

— McKinsey & Company

We’re here to help you on that journey.