Accelerated development cycles through synergistic technologies

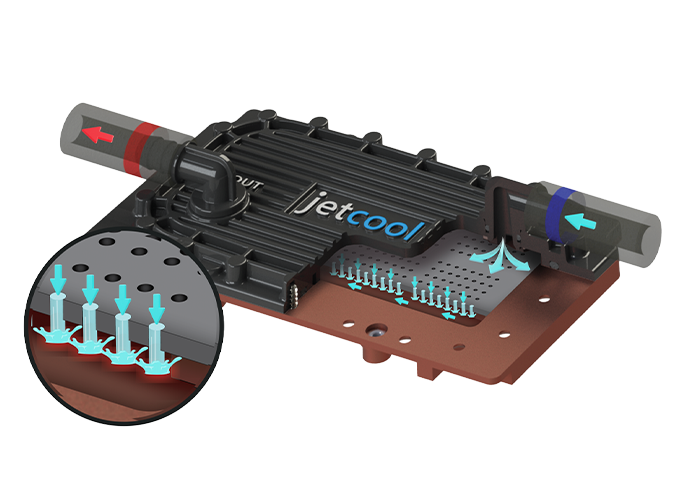

By combining Flex’s high-volume manufacturing expertise with JetCool’s patented microconvective cooling® technology, hyperscalers can deploy advanced AI and HPC systems with reduced time-to-market. JetCool’s microjet technology leverages impinging microjets to achieve a significantly lower thermal resistance compared to conventional microchannel cooling.

This innovation drives superior heat extraction at the die level, accelerating thermal management optimization and enabling higher performance densities. The integration of microjet cooling within Flex’s system designs reduces temperature gradients and supports a more uniform thermal distribution across complex silicon architectures.

Advanced liquid cooling enhances thermal density

JetCool’s direct-to-chip liquid cooling (D2C) technology is a differentiator among cooling technologies due to its ability to target heat flux concentrations within the chip architecture.

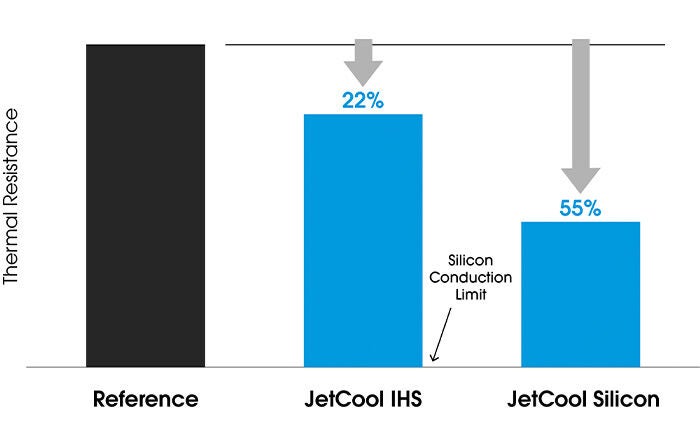

Figure 1. Thermal performance benefits of reducing spreading

As die architectures become more complex, heat flux distributions have tended to become more nonuniform. In addition, chip packaging has evolved to favor cooling solutions that attach directly to the die, moving away from integral heat spreaders.

Even with integral heat spreaders, significant nonuniformity in the heat flux can persist (e.g. AMD EPYC) and performance gains through hot spot targeting, which drives down maximum temperatures, can be achieved using JetCool’s microconvective cooling technology (Figure 1).

The ability to tailor heat transfer distribution in the cooling solution drives a more uniform die temperature, reduces thermal stresses in the die and maximizes chip lifespan. Importantly, the ability to tailor the cooling configuration within the chip does not have any native size limitations and cooling larger dies does not produce larger temperature non-uniformity or larger pressure drop, as might be expected with competing technologies.

Optimizing the cooling configuration using JetCool’s microconvective cooling approach and bringing cooling closer to the chip doesn’t just provide the benefit of more uniform die temperatures; the efficiency of the die itself is improved.

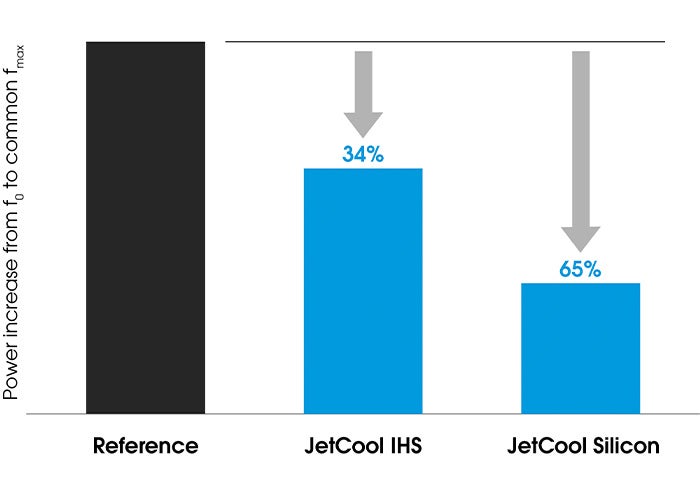

Improving cooling by bringing it closer to the chip and focusing heat transfer on the highest heat flux areas of the silicon can reduce the power increase needed to boost the processor operating frequency by 65% (Figure 2).

JetCool’s product portfolio addresses the entire range of today’s chip cooling challenges, both in terms of total power—cooling chipsets beyond 1500W today—and successfully taming heat flux magnitudes well above 5 W/mm2. These solutions range from fully enclosed cold plates, SmartPlates, operating with or without area enhancement to our direct to die solution, to SmartLids, which seals directly to the chip package for even greater cooling performance.

Figure 2. Reduced power requirement to boost the processor operating frequency

JetCool’s portfolio of cooling technologies prepares hyperscalers for the future, enabling skyrocketing heat loads and heat flux magnitudes without needing to resort to two-phase cooling. JetCool will enable next generation chipsets without concerns about transient operation or cliff-edge effects such as critical heat flux, which represent important issues unique to two-phase cooling.

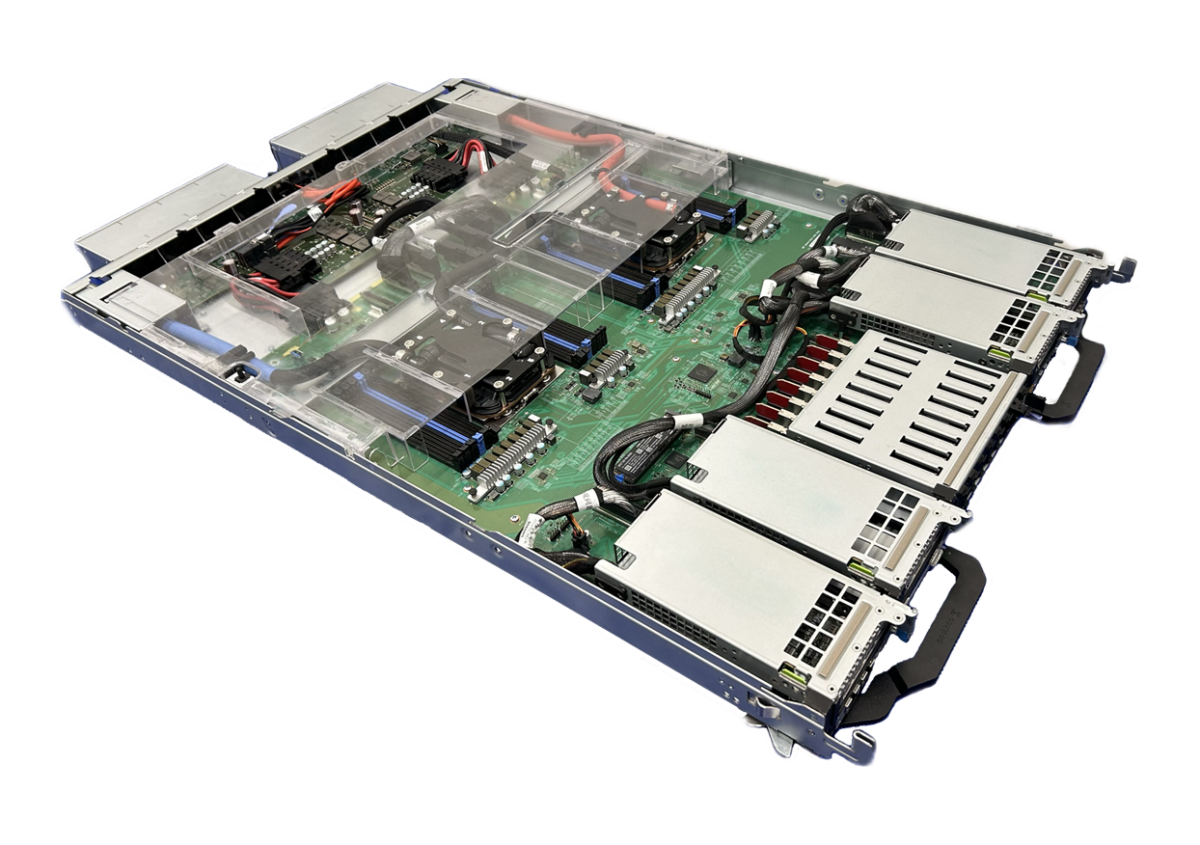

Scalable liquid-cooled racks for AI and HPC workloads

Flex’s power optimization solutions

Flex’s suite of power distribution and management solutions complements JetCool’s thermal technologies, creating a complete rack-level system that maximizes power utilization and minimizes energy losses.

Download the white paper