MachineMax was born from a collaboration between Royal Dutch Shell and BCG Digital Ventures with the objective of tracking and managing every off-highway machine on earth. This ambitious start-up wanted to launch a game-changing and easy-to-deploy machine analytics service to track and manage heavy machinery and help customers maximize the profitability of every machine in their fleet.

The challenge

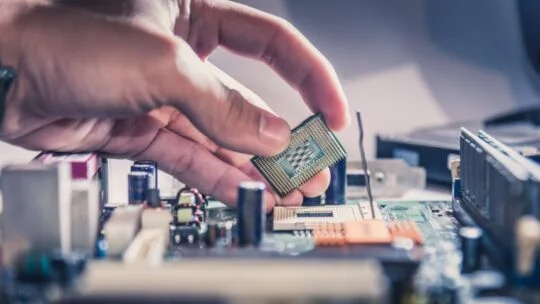

As MachineMax set about testing prototypes of a wireless telematic device that could analyze and transmit usage data, it became obvious they would need a partner to build and scale production of the hardware devices. For any startup, delays of a few months can be costly, or even fatal.

MachineMax needed a partner to guide them through the innovation, prototyping, production, and logistics processes and scale internationally from day one.

The solution

A simple internet search and email connected MachineMax with us. We had already developed a platform for the pre-launch testing of Internet of Things devices, called iENBL. This platform allowed MachineMax to fast-track its development and test its solution in the field with working prototypes without investing in custom builds. This meant that the volume production and certification process could be carried out with minimal delay.

The result

We helped MachineMax get from a conceptual design to a device ready for volume production in less than a year, which is half the time it would have taken using any other partner. The collaboration enabled MachineMax to test its product straightaway without the custom build of a test device. And when the finished unit was ready, we manufactured it quickly and at scale for international deployment.