We collaborate with leading brands all over the world to meet their automated manufacturing needs, whether that’s to reach scale for high-volume demands, achieve world-class quality, or build products closer to end-markets.

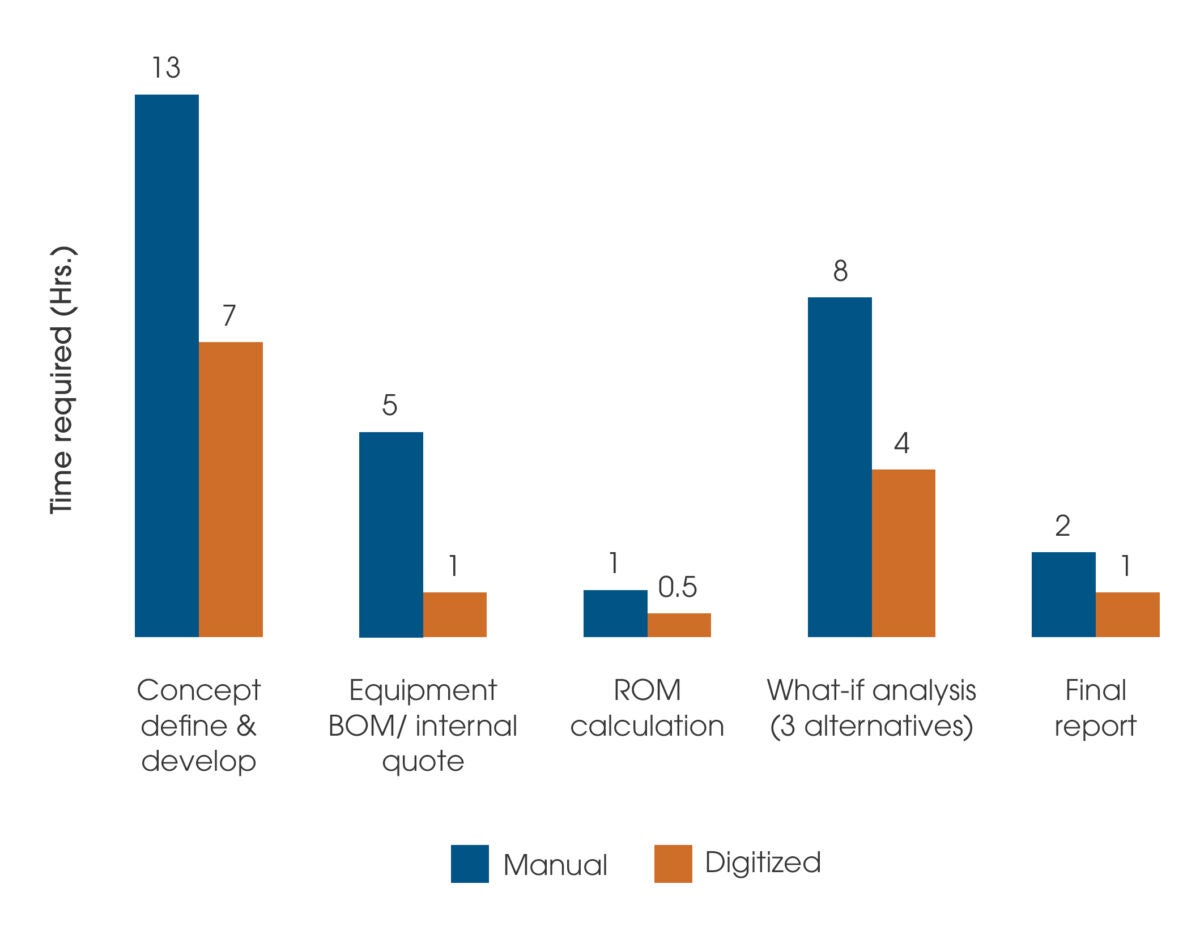

Time to market is always a critical consideration when transitioning to automated manufacturing. To help speed this process for our customers, we developed an innovative digital approach that leverages simulation to optimize both product design and manufacturing lines for automation.

Flex’s Design for Automation solutions are digitized, standardized, centralized capabilities that automatically track assumptions and perform “what if” analyses to understand downstream effects and find the optimal solution.

We help verify your product design to prepare for automated manufacturing.

Using a rules database, we analyze product design assembly, checking elements such as part spacing, interference, and keep-out. We then collaborate with our customers to identify what areas of the product’s computer-aided design (CAD) need modification to conform to the spacing rules for automation before delivering a visual report.

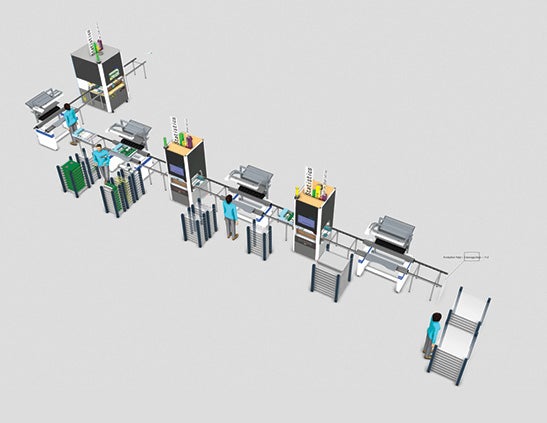

With our Digital Design for Automation Line capabilities, we help our customers conceptualize and validate automated manufacturing assembly lines.

Our automation engineers use active components and templates to automatically generate reports to validate a range of variables, including cycle time, robot reachability, space, collisions, and Rough Order of Magnitude (ROM) quotes.

Flex’s Design for Automation capabilities help eliminate the inaccuracy of traditional, manual “what if” analyses and take the guesswork out of optimizing the manufacturing solution design process. With our digital approach, we support our customers’ global manufacturing needs, ensuring ongoing resiliency and fueling increased efficiency by removing geographic barriers for knowledge sharing and production.

To optimize automated manufacturing solutions and reduce concept generation and validation times, our engineers leverage an enhanced simulation tool with a custom logic, user interface, and workflows. Our Design for Automation capabilities help you develop custom automation solutions and benchmark and validate concepts for turnkey solutions needed to get your product to market faster.

With our database containing more than 16,000 rule items, we can provide product design feedback to our customers based on specific product types or business segments. Our database of automation components can also be used for faster modeling and validation of automated manufacturing systems.

To optimize the design of an automated manufacturing line, we manage the simulation process so that all stakeholders can more easily collaborate on design reviews of the mechanical parts and components that go into the production line. We leverage a plug-in for SOLIDWORKS 3D CAD design software to develop a CAD of the product, the process flow, and a bill of materials (BOM) to analyze whether the product assembly can be automated. Through this process, we help our customers simulate and validate automation and can easily share best practices with multiple sites globally to support in-region manufacturing.