Die globale Gesundheitslandschaft erlebt heute eine rasante Entwicklung, die vor allem durch eine wachsende alternde Bevölkerung und die Nachfrage nach minimalinvasiven Behandlungen vorangetrieben wird, die die Patientenversorgung vereinfachen und verbessern. Als Reaktion darauf hat sich der Markt für medizinische Optik als zentrale Kraft bei der Transformation der Gesundheitsversorgung herauskristallisiert. Die Zahlen belegen dies: Laut Precedence Research wird der Optikmarkt im Jahr 2022 $200 Milliarden USD überschreiten und die zukünftige Nachfrage wird nur noch weiter wachsen.

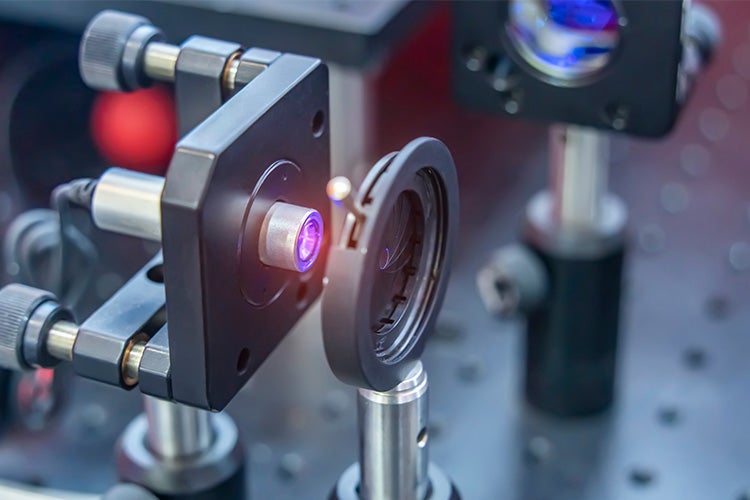

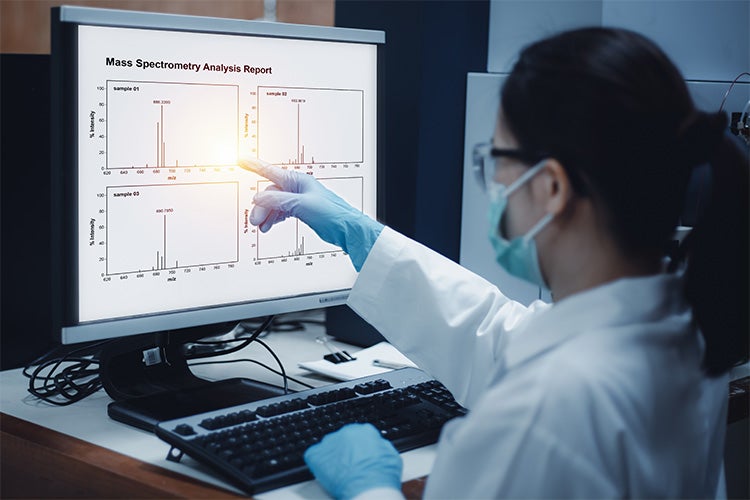

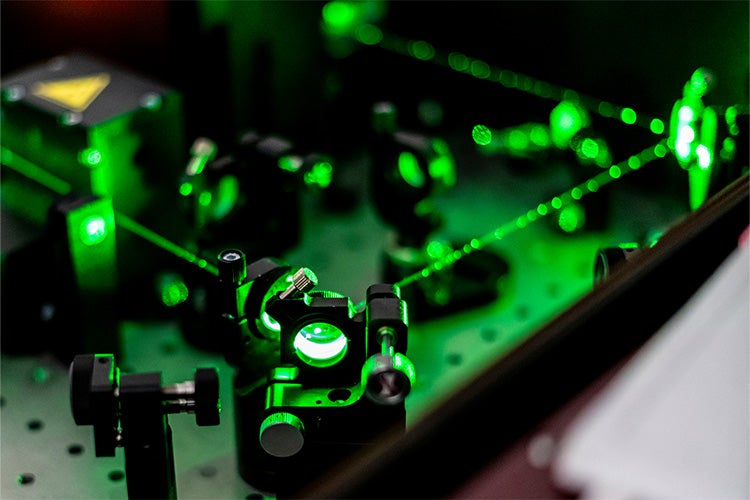

In medizinische GeräteOptiken können Bildgebung, medizinische Laseranwendungen oder andere photonische Baugruppen kombinieren. Beispiele hierfür sind miniaturisierte Diagnoseprodukte für den Heimgebrauch, In-vitro-Diagnostika (IVD) für den Einsatz in Krankenhäusern und Kliniken, Point-of-Care-Geräte, Scanner, ophthalmische Geräte sowie endoskopische und chirurgische Anwendungen.

Die Priorisierung von Fortschritten bei optischen Lösungen kann sich sowohl positiv auf die Patientenversorgung als auch auf die Produktdifferenzierung eines Unternehmens auswirken. Durch die Nutzung optischer Fortschritte können Gesundheitsunternehmen die Markteinführungszeit verkürzen, die Produktentwicklungskosten senken und Präzision und Qualität steigern.

Diese Marktchancen veranlassen Hersteller medizinischer Produkte dazu, sich Fachwissen und durchgängige Kapazitäten im Bereich Optik zuzulegen, um die Entwicklung neuer Produkte zu optimieren und die Herausforderungen der Miniaturisierung, Einhaltung gesetzlicher Vorschriften, Lieferkettenunterbrechungen, Tests und mehr souverän zu meistern.

Laden Sie die Broschüre zu den optischen Funktionen des Flex für medizinische Produkte herunter