¿La medida ha dado paso a la estandarización?

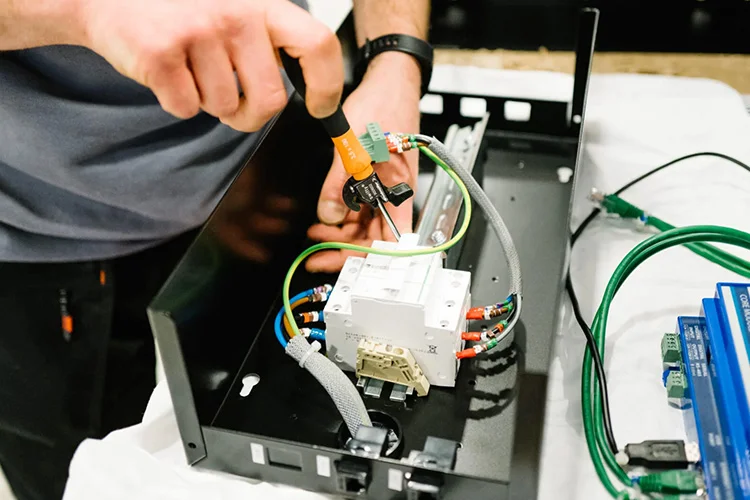

Seguimos desarrollando según las necesidades específicas de nuestros clientes y los requisitos regionales, pero como hemos visto a través de iniciativas como el Open Compute Project (OCP), la estandarización, la modularización y la replicación son la forma más rápida de escalar. Todos nuestros clientes me hablan de componentes básicos como las CDU., PDU, y módulos de energía: sistemas preconfigurados, precomisionados, preprobados y prevalidados que desbloquean la escala que necesitan.

¿Quién es el héroe anónimo en todo esto?

Velocidad de implementación. Una vez seleccionado el sitio y asegurado el acceso a la energía, el plazo de construcción de un centro de datos a hiperescala es de aproximadamente 18 meses, y cualquier operador de centro de datos lo acortaría si pudiera. Por lo tanto, lo que sucede después de la fabricación es crucial, desde la entrega en el lugar y momento adecuados hasta la puesta en marcha, la inspección y la activación. Cuanto más podamos hacer en la fábrica, más rápido podrán trabajar en el sitio. ¿Y si pudiéramos reducirlo a entre 30 y 60 días? Quizás la clave no se encuentre solo en la tecnología. Es la capacidad de reducir el tiempo que tardan nuestros clientes de centros de datos en estar operativos.

Es una de las razones por las que Flex continúa expandiendo su capacidad de fabricación mediante la reutilización de espacios, el arrendamiento de instalaciones, la adquisición de empresas complementarias y el establecimiento de alianzas estratégicas. Desarrollar cadenas de suministro ágiles y resilientes también es un factor importante en esa ecuación.

Esta es una industria en rápida evolución. ¿Qué más piensa sobre el futuro de la energía en los centros de datos?

Las limitaciones de la red eléctrica no desaparecerán pronto, y los operadores de centros de datos están explorando la generación de energía in situ, más allá de los generadores de respaldo, para garantizar el rendimiento, la fiabilidad y la escalabilidad. ¿Cómo afectarán los módulos nucleares in situ, las microrredes solares, eólicas y geotérmicas, las turbinas de gas natural y otras fuentes de energía a la infraestructura eléctrica del centro de datos y su interacción con la red eléctrica? ¿Eliminarán o agravarán la escasez de equipos?

En Flex, nos centramos principalmente en la gestión y transmisión de energía en lugar de cómo se genera, pero tenemos experiencia en energía de servicios públicos que va mucho más allá de una implementación de centro de datos estándar y estamos entusiasmados de poder aprovechar esa amplia base de conocimiento en estas discusiones de la industria.

Si hay algo que falta en esta ecuación de creación de capacidad, ¿qué es?

Preparación de la fuerza laboral. Todos hemos oído hablar de la escasez de electricistas, fontaneros y otros profesionales necesarios para desarrollar la capacidad, pero pocos hablan de las personas necesarias para inspeccionar y poner en marcha proyectos o solucionar problemas de calidad y eficiencia energética, entre otras habilidades. Y tampoco hay mucha gente que comprenda las arquitecturas de energía de última generación de +/- 400 VCC y 800 VCC. Prepararse para el futuro no se trata solo de tecnología. Se trata de talento. Hay... carreras gratificantes En el sector energético. Necesitamos abrir camino a la gente. Creo que es un momento muy emocionante en una gran industria.